The WESTKÜSTE100

real-world laboratory

in detail

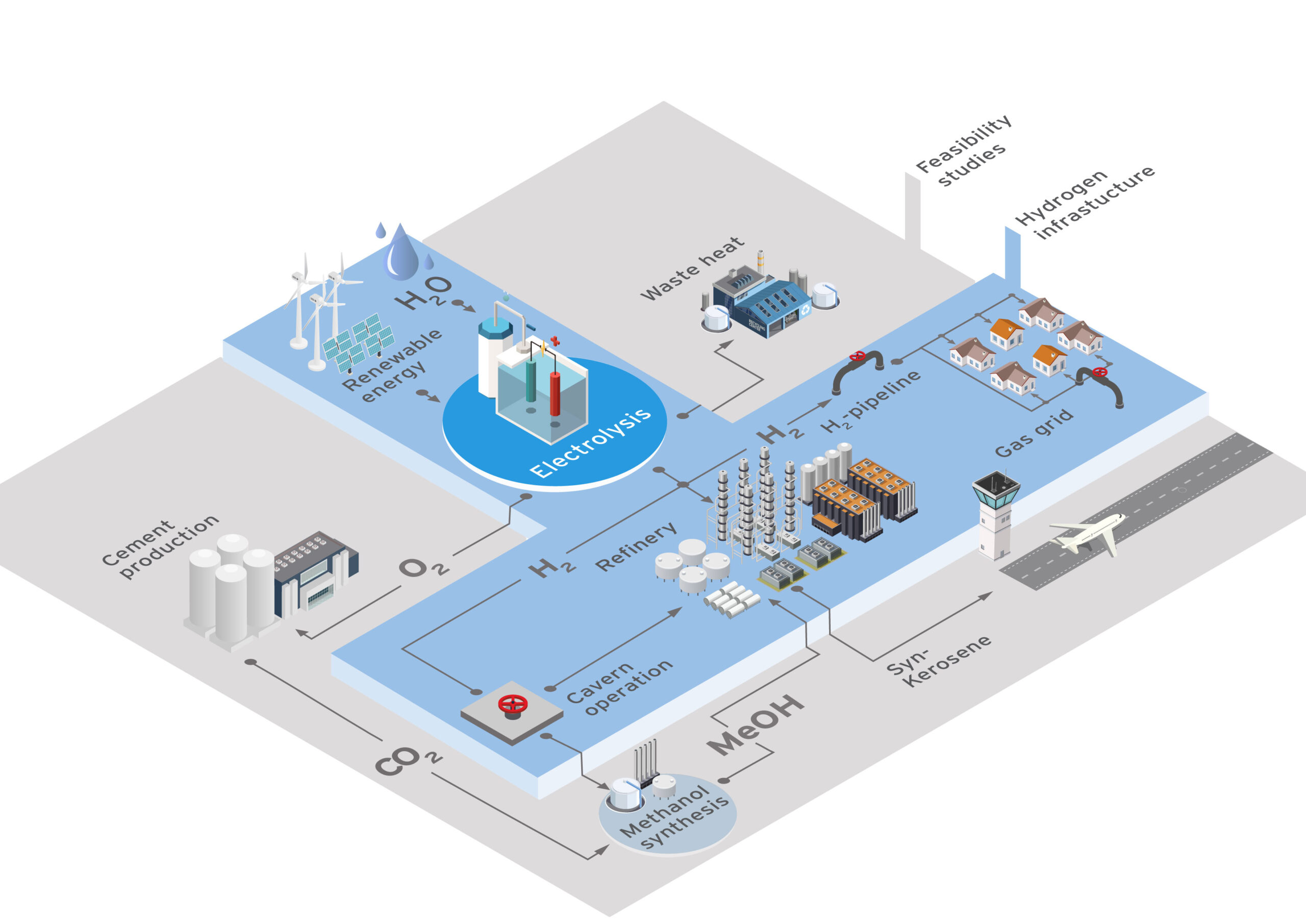

In the project period of the real-world laboratory from 2020 to 2025, with the operation of the electrolyser and the subsequent use of the green hydrogen, fundamental economic, technological and scientific findings will be obtained. For only sound knowledge on the energy and material cycles, as well as its feasibility, will make any future scaling up of the project possible. Cross-sector, closed value creation chains in the region should emerge in this way.

The electrolyser will be integrated into the existing refinery process in order to demonstrate the production and direct industrial use of hydrogen. A cavern system, i.e. a storage system, located nearby, will be re-purposed as interim storage for the hydrogen generated, and, if required, provide it for industrial use. A hydrogen grid between the refinery, the cavern and Heide Municipal Utilities (SWH) will be created in parallel. Innovative pipeline technology in the grid section between Raffinerie Heide and Heide Municipal Utilities will be put into operation for the first time. In this section of the project, the partners will investigate how hydrogen can be integrated into the existing gas infrastructure in the long term. Through the admixing of green hydrogen in one section of an existing gas grid a contribution towards the decarbonisation of the supply of heat will be highlighted.

In two feasibility studies, it will additionally be examined how the oxygen produced during the electrolysis can be fed by means of a so-called “oxyfuel process” into the firing process of the cement works in Lägerdorf, and carbon dioxide (CO2) subsequently be separated off. With the aid of the CO2 from the cement works and the hydrogen from the electrolyser, a plant for the synthesis of methyl alcohol could be operated in future. Following this, the exhaust gas can be further processed to make high-purity CO2 as a starting substance for the chemical industry, and deployed as a raw material in other business sectors. The studies provide fundamental data on the technical and economic feasibility of the downstream CO2-extraction, treatment and re-routing for downstream methanol synthesis. The process of the methyl alcohol synthesis can, in a step downstream from the WESTKÜSTE100 project, be a basis for the production of synthetic fuels, such as aviation fuel. In addition, the question of whether and how the waste heat arising in the electrolysis procedure can be used will be examined separately within the scope of WESTKÜSTE100.

The various sub-projects of the WESTKÜSTE100 real-world laboratory ultimately provide integrated technical, commercial and scientific findings. These fundamental insights are the prerequisite for implementing the decarbonisation of the industry, the supply of heat, chemistry and mobility with an electrolysis output capacity of several hundred megawatts planned by the WESTKÜSTE100 partners following the conclusion of the project in the year 2025.

Sub-projects of the real-world laboratory

The “WESTKÜSTE100” real-world laboratory is sub-divided into seven main work packages (MWPs), which deal with the testing of various different material life cycles and provide findings on the economic and technological implementation of the project on a large scale.

Concept and test-run of a

30-MW-electrolysis facility

RHG100

Details

In the Main Work Package (MWP) 1, a 30 MW electrolysis facility for generating green hydrogen using energy from renewable sources of energy will be planned, constructed and put into operation. The “H2 Westküste GmbH” Joint Venture for this purpose, consisting of Hynamics Deutschland, Ørsted Deutschland and Raffinerie Heide, was established. The electrolysis facility will be installed in Raffinerie Heide site. The facility will be integrated for a large-scale demonstration of the generation and use of green hydrogen in the existing industrial process of the refinery. Besides planning, developing and constructing the electrolyser, including the connected auxiliary systems, and selecting a suitable electrolysis method, the joint venture partners will also observe and process all associated approval aspects. From the operation of the electrolyser, insights into the maintenance, control and operational concepts will be gathered for the WESTKÜSTE100 real-world laboratory project.

Set up of a hydrogen pipeline grid

PIPE100

Details

In the Main Work Package (MWP) 2, the Stadtwerke Heide (Heide Municipal Utilities, SWH), Thüga and Open Grid Europe (OGE) will demonstrate how the supply of heat can be partially decarbonised or defossilised rather rapidly with a low investment. OGE will set up a hydrogen pipeline, where one line section will be made of steel and another line section will be made of plastic. The hydrogen will travel via the pipeline from the electrolyser at Raffinerie Heide, to the Heide Municipal Utilities site. There, the hydrogen will be fed into a portion of a grid area with a proportion of up to 20 vol. %, to around 200 households. The focus will firstly be placed on checking the suitability of the new gas transport system for hydrogen. Secondly, Thüga and SWH wish to demonstrate that the components of a modern existing gas grid, including the installations at customers’ premises, fulfil all the requirements for feeding in hydrogen in practice. Additionally, the project will deliver empirical values on the supply characteristics of the new source of energy on the heating market. OGE researches in this project how hydrogen can be integrated into the existing gas infrastructure in the long term. For that purpose, a complete hydrogen infrastructure will be built to mimic the natural gas grid, and tested in a real-life scenario over the course of several years’ operation.

verbunden über Pipeline

Details

Within the Main Work Package (MWP) 3, work will be carried out on re-purposing and upgrading a cavern, not far from Raffinerie Heide, for storing the green hydrogen from the 30 MW electrolysis facility. The cavern will serve as a long-term and buffer tank in the overall system of WESTKÜSTE100. By storing the hydrogen, it will be possible to transfer the available renewable sources of energy, such as wind power, into a continuous stream of material for industrial use. Thus, the green hydrogen will also be available in times of insufficient wind or sun. After putting the cavern into operation, the aim is to obtain additional insights into the control performance, response speeds and data on the optimum integration of the cavern into a fluctuating system, and formulate a scaling up to an electrolysis output of several hundred megawatts. Besides a suitability check, the design and implementation of the underground upgrading of the cavern to store green hydrogen, as well as the construction of a hydrogen transfer route, all the legal approval-related aspects also form part of the project work in MWP 3.

exchanging

Feasibility studies for preparing a scenario with several hundred megawatts

OXY100

Feasibility study: Conversion of cement factory Lägerdorf to Oxyfuel process

Details

The aim of the Main Work Package (MWP) 4 is to carry out two feasibility studies on the conversion of the cement works in Lägerdorf to a second-generation oxyfuel process. The studies should provide reliable data on the technical and economic feasibility of the downstream CO2-extraction, treatment and re-routing for downstream methyl alcohol synthesis in cement works and lay the foundation for the investment decision regarding the implementation. The oxygen obtained through electrolysis needs to be transported to the cement works in Lägerdorf, where it will be fed in the future into the firing process. Virtually 100 per cent of the CO2 emissions from the cement manufacture could be removed using this process. The exhaust gas can subsequently be treated to become a high-purity CO2 gas as a starting substance for the chemical industry, and be deployed as a raw material in other business sectors. The results from the study will give the go-ahead for the conversion of the cement works.

MeOH100

Feasibility study of a

Methanol synthesis plant

Details

The goal of the Main Work Package (MWP) 5 is a feasibility study for a methyl alcohol synthesis facility, which uses the CO2 from a cement works and a refinery, and hydrogen from water electrolysis operated with renewable energy sources as raw materials. With large-scale hydrogen production and the decarbonisation of two industries (the petrochemical and cement industries), the planned project addresses significant climate protection targets. The technological challenge is to integrate the methyl alcohol synthesis between cement works – as a CO2 point source – and the downstream processes of a refinery for the first time. The process thus needs to be matched, on the one hand, to the specific parameters of the cement works, and, on the other hand, to the manufacture of aviation fuel in the refinery. The MWP 5 will be managed, and predominantly carried out, by thyssenkrupp. The project partner Hynamics Deutschland will provide assistance with the details of the integration into the existing infrastructure.

Total system integration (collaterally)

Details

The aim of the Main Work Package (MWP) 6 “Total system integration” is to merge the insights obtained from MWP 1 to 5. With the findings from MWP 1 to MWP 5, in MWP 6 the process technology and operative overall integration of the connected systems from the fields of power connection, electrolysis system, refinery connection and cavern storage, as well as all the recipients for the hydrogen (refinery, natural gas grid, hydrogen station) will initially be tried out with an electrolysis capacity of 30 MW. That includes the co-ordination of the plant engineering and the mass flows, as well as the review of more flexible operating modes for investigating interactions and the exploration of optimised and resilient power grid integrations. HAP 6 should provide the technical and commercial insights that are needed to be able to implement the integrated decarbonisation of industry with an electrolysis capacity of several hundred megawatts, planned by the WESTKÜSTE 100 partners, once the project has been concluded in the year 2025.

Societial transformation (collaterally)

Details

In the Main Work Package (MWP) 7, the interactions of the project with the environment and society will be the focus of attention. This includes four aspects: In the Work Package (WP) 7.1, energy and greenhouse gas balances will be drawn up, divided by sector and sub-sector, and the politically agreed climate targets specified by setting requirements on the technical implementation. The WP 7.2 will assist the project in continuing to develop the regulatory framework and the recommendations for action. Amongst others, the amendments of the Renewable Energies Act (EEG) and the RED II with the Delegated Acts of the EU, as well as the implementation in national law and the German Federal Immission Control Act will be considered. In the WP 7.3, the communication of the entire project, as well as the regionally participative and media integration of the project – e.g. into the 100% renewable energies series of the Heide Region development agency – will be examined, in order to ensure social acceptance for further energy transition projects in the field of hydrogen. A somewhat broader task is pursued by WP 7.4, where the socio-economic interactions of the emerging hydrogen economy with society will be examined. For this purpose, sustainable development scenarios for the regional hydrogen economy will be drafted, and made available to political decision-makers. Proposals for the supra-regional cross-linking of the project will also be developed.

The vision: The 2025+ scenario

Details

At the WESTKÜSTE100 real-world laboratory, by 2025 an electrolysis facility with an output of 30 megawatts should provide insights into its operation, maintenance and control, in order to move on to the next scaling stage. This would require an electrolyser with several hundred megawatts, for which the electricity could be supplied via a direct connection to an offshore wind farm.